Diaphragm, supensions…

A great amount of studies done by our partner Atohm’s research and development team directed by Thierry COMTE led them to understand that the properties of the diaphragm material do indeed have a great influence on frequency response. However, the overall result is very closely affected by factors such as the rigidity and length of the coil former, the mass of the winding, the nature and quantity of adhesive used for the former/diaphragm seal, as well as the geometry, mass and viscoelastic properties of the peripheral suspension. Perfect “piston” movement by the diaphragm only exists for a limited frequency range. The directivity of a perfect piston always remains proportional to the dimensions of its emissive surface (and not its rigidity).

The different cone and suspension break-up modes increase or reduce the sound pressure according to their amplitudes and phases. Beyond certain frequencies, the coil support ceases to transmit the movement and is deformed due to combined action of the cone and the mass of the winding. This buckling also plays a part in reinforcing or cancelling the overall displacement of the cone (you could say that the support acts like a “spring”). The moving parts unit forms an “indivisible whole”. As such, this “whole” needs to be optimized according to the goals to be achieved, without forgetting the absolute necessity of guaranteeing reliability and quality reproduction.

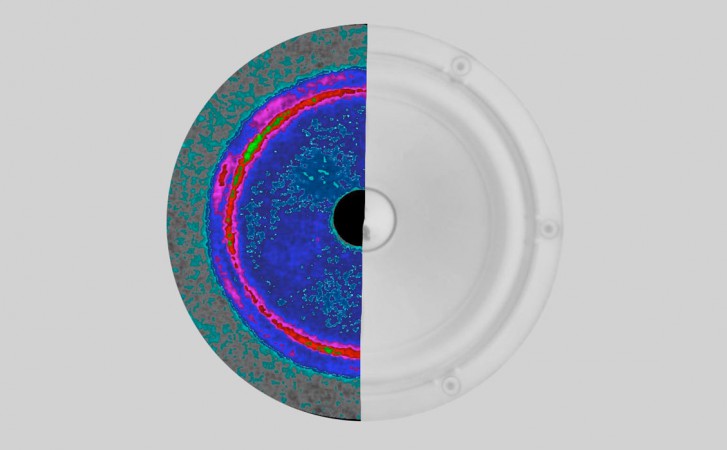

Cone movement is perfectly uniform (in blue). In the low frequency, only part of the suspension’s surface is emissive. At 1000 Hz, the total suspension is emissive (provoking excess amplitude in the frequency response). The specific profile (LDS™ Technology) makes up for this excess amplitude by impending part of the suspension’s surface (in red).

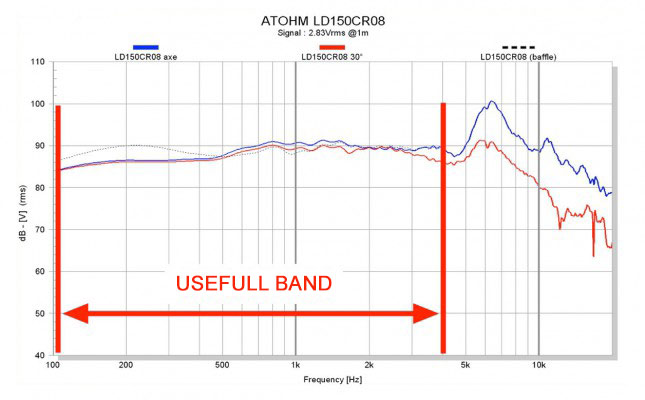

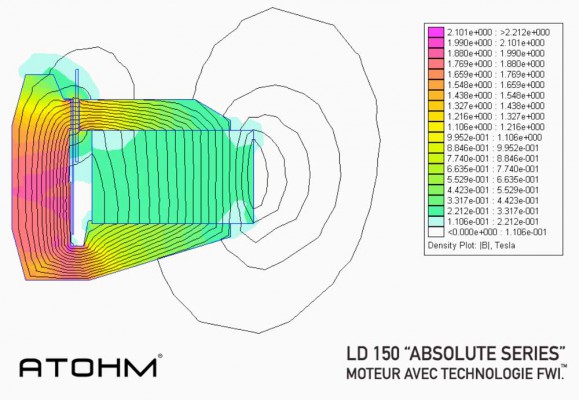

The goal was to produce bass/midrange drivers with a frequency response very close to the ideal, between 30 Hz and 4000 Hz. With these considerations in mind, the drivers’ cone are fitted with a diaphragm made out of special alloy, aimed at expulsing the audible break-ups out of this useful frequency range. Similarly, the cone is combined with a coil former made out of Kapton/Nomex in order to ensure perfect movement transmission in this nominal frequency range. In addition, this support with its adhesive seal, limits the transmission and absorbs part of the energy. These units have also been fitted with a peripheral suspension featuring a special profile which favors progressive break-up (LDS™ Technology) without noticeable hitches in the useful frequency range (typically between 700 Hz and 1800 Hz for the LD150).

Drawing on simulations (finite element method) and measurements by laser interferometry, Atohm’s team optimized the numerous interactions and made precise adjustments to the geometry of the moving parts unit. The frequency response of the driver is characterized by exceptional linearity along the useful frequency range. Further along, the response is corrected with an adapted filter. By using rigid materials and perfectly stable adhesives, the performances are entirely duplicable from one unit to another maintaining a high degree of precision (which cannot be said for a paper diaphragm or one made from Kevlar®, for example).

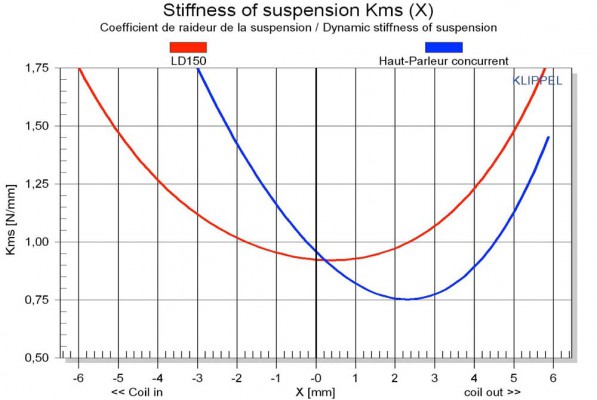

The bass/midrange drivers Absolute Series was the object of a great deal of research aimed at getting as close as possible to the ideal functioning parameters. The loudspeaker is an electromechanical unit featuring a diaphragm which reproduces the musical signal by oscillating around its rest position (point 0). The driver diaphragm must, therefore, oscillate perfectly symmetrically around this position. Its movement must be identical and proportional to the excitation signal. However, its elements (suspensions) and the electromechanical characteristics of the motor (force factor, inductance…) are subject to variations which change the “theoretical” movements of the diaphragm. These variations, also known as “non-linearities”, have an effect on the excursion of the moving parts and create what is more commonly known as distortion. These are the factors which determine and limit the excursion capabilities of the moving parts.

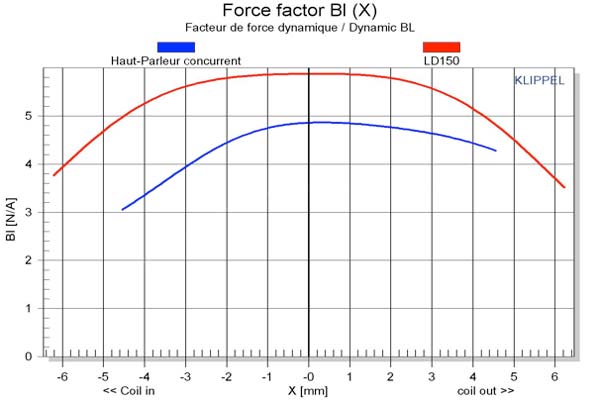

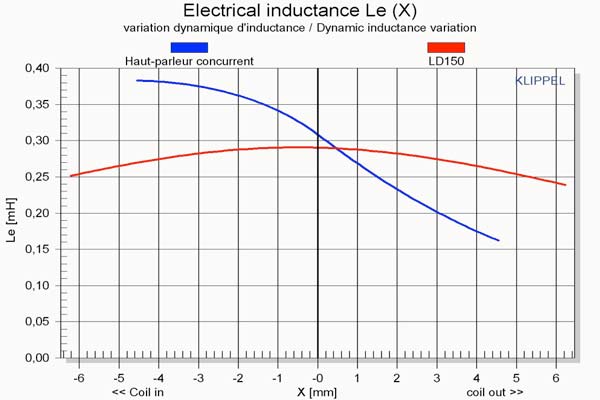

Based on that assumption, particular care was taken in designing these transducers, using powerful modeling tools in order to reduce all forms of distortion. The different parameters to be taken into account and optimized as far as possible were: the symmetry and the linearity of the stiffness coefficient of the suspensions (dynamic stiffness coefficient curve of the suspensions), the force factor resulting from the current running through the coil and the magnetic flow concentrated in the air-gap (dynamic force factor curve), as well as stability of the inductive value of the loudspeaker coil (dynamic inductance variation curve).

The goal was to produce bass/midrange drivers with a frequency response very close to the ideal, between 30 Hz and 4000 Hz. With these considerations in mind, the drivers’ cone are fitted with a diaphragm made out of special alloy, aimed at expulsing the audible break-ups out of this useful frequency range. Similarly, the cone is combined with a coil former made out of Kapton/Nomex in order to ensure perfect movement transmission in this nominal frequency range. In addition, this support with its adhesive seal, limits the transmission and absorbs part of the energy. These units have also been fitted with a peripheral suspension featuring a special profile which favors progressive break-up (LDS™ Technology) without noticeable hitches in the useful frequency range (typically between 700 Hz and 1800 Hz for the LD150).

Drawing on simulations (finite element method) and measurements by laser interferometry, Atohm’s team optimized the numerous interactions and made precise adjustments to the geometry of the moving parts unit. The frequency response of the driver is characterized by exceptional linearity along the useful frequency range. Further along, the response is corrected with an adapted filter. By using rigid materials and perfectly stable adhesives, the performances are entirely duplicable from one unit to another maintaining a high degree of precision (which cannot be said for a paper diaphragm or one made from Kevlar®, for example).

AS YOU CAN SEE ON THE CURVE ON THE RIGHT, THE KLIPPEL® SYSTEM MAPS THE STIFFNESS COEFFICIENT RESULTING FROM THE SUM OF THE PERIPHERAL AND CENTRAL SUSPENSIONS (KMS) ACCORDING TO THE EXCURSIONS OF THE MOVING PARTS (X). TO THE LEFT OF POINT 0, THE EXCURSION IS NEGATIVE, CORRESPONDING TO THE COIL ENTERING THE MOTOR AND TO THE RIGHT OF POINT 0, THE EXCURSION IS POSITIVE, CORRESPONDING TO THE COIL’S EXIT FROM THE MOTOR.

THE BLUE CURVE REPRESENTS THE MEASUREMENTS TAKEN FROM A COMPETITOR’S LOUDSPEAKER. YOU MAY NOTICE THAT THE ASYMMETRIC COEFFICIENT IS VERY HIGH… THE MINIMAL STIFFNESS POINT IS SITUATED AT ABOUT +2MM FROM THE REST POSITION. DURING ITS EXCURSIONS, THE DIAPHRAGM THEREFORE TENDS “TO GO BACK TO” THIS MINIMAL POINT INSTEAD OF OSCILLATING FREELY AROUND THE POSITION 0. THE RED CURVE REPRESENTS THE MEASUREMENTS FOR THE LD150. IT IS ALMOST SYMMETRICAL IN TERMS OF THE STIFFNESS COEFFICIENT, REPRESENTING BETTER MECHANICAL POWER HANDLING, IMPROVED DYNAMIC CAPACITIES AND REDUCED DISTORTION.

REDUCING DISTORTION, IT IS RENDERING THE STIFFNESS COEFFICIENT AS LINEAR AND SYMMETRICAL AS POSSIBLE OVER A BROAD EXCURSION RANGE.

ATOHM’s « Absolute Series » drivers are equipped with exclusive frames made out of injected aluminum. Their shapes were designed according to their functions and take into account mechanical, acoustic, thermical and aesthetical constraints.

The ATOHM’s frame is extremely rigid, providing the perfect mechanical support to the driver unit as a whole. Thanks to its thick, ribbed crown shape, it is attached firmly to the cabinet. Altogether it has 18 fine spokes which play an excellent role in optimizing rear wave flow. The rear volume of the spider features tiny openings which provide adequate ventilation, and also limit the possibility of potentially harmful particles entering the volume. The motor is fixed solidly to the frame along a wide base plane using screws and special adhesive. Finally, due to its material composition and the large surface area, the basket plays an active role in cooling the loudspeaker by evacuating the calories accumulated within the motor.

History

Materials

Technology

Joseph Kirby

Phone: 817-822-6387

eMail: joseph.kirby@getatsdesign.com

© Waterfall Audio 2023